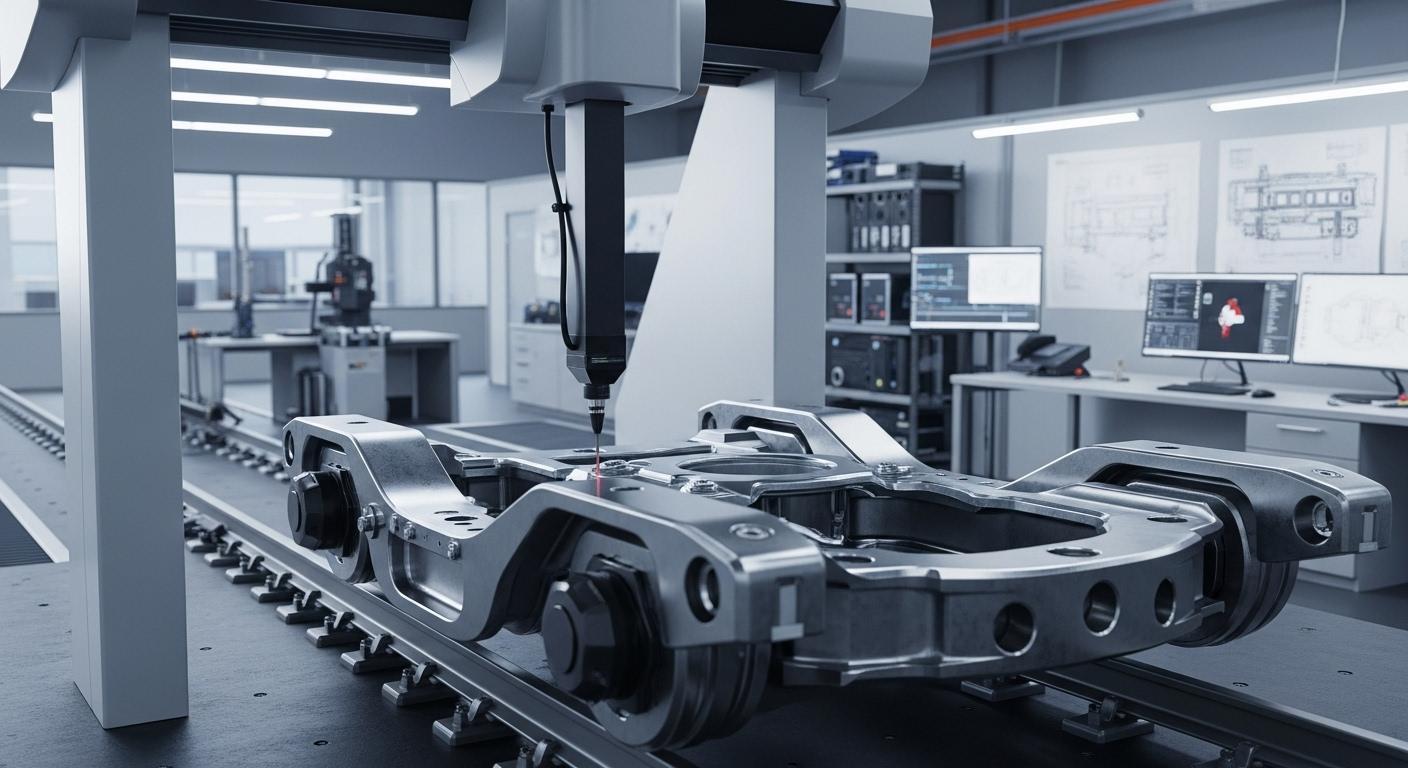

Quality control in the railway sector is of critical importance for safety. At Macstoff, we offer measurement and control services with millimetric precision using CMM (Coordinate Measuring Machine) technology.

What is CMM?

A Coordinate Measuring Machine is a computer-controlled system that measures three-dimensional geometries with high precision. This technology allows us to control the dimensional accuracy of complex parts at the micron level.

CMM Applications in Railways

- Rail Fasteners: Precise measurement of critical connection points

- Wagon Components: Control of critical parts for safety

- Lock Mechanisms: Measurement of parts requiring precise tolerances

- Brake Systems: Control of vital components for safety

Our Quality Process

We perform CMM control at every stage of the production process:

- Initial Part Inspection: Quality verification at the beginning of production

- In-Process Control: Regular quality tracking during production

- Final Inspection: Comprehensive measurement before shipment

- Documentation: Digital archiving of all measurements

Our Technological Advantages

In our 8,000 m² production facility, we have 20 workstations equipped with the latest CMM devices. All measurements are conducted in accordance with ISO 9001 and railway industry standards.

Following the principle "Excellence is not a goal, but a habit", we continue to make continuous investments in quality.